Research into advanced materials is pivotal for discovering and tailoring materials to meet the demands of challenging environments. Materials for Demanding Environments (M4DE) was our comprehensive doctoral training programme designed to address complex industrial challenges while fostering interdisciplinary skills and expertise. This initiative provided students with unparalleled access to industry collaborations and cutting-edge facilities.

Programme overview

M4DE's four-year doctoral research programme brought together PhD students, academics, and industrialists to tackle the complex challenges faced by industry partners. Collaboration with industrial partners resulted in a suite of Aerospace, Oil and Gas, and Nuclear case studies, addressing real-world challenges and the need for materials to perform optimally in demanding environments.

-

Industry collaboration

Students conducted a diverse range of research projects working in collaboration wtih industry. These projects were sponsored by our partners across a variety of areas.

Discover further benefits of a CDT programme

-

Schools, colleges and the public

A key part of the M4DE CDT programme was public engagement and outreach activities, with each student taking part in supporting local schools and research placements.

Outreach is key to our Faculty's social responsibility

Training

The CDT gives us the opportunity of doing world class research on relevant and modern topics in collaboration with industrial and technological companies and this is the reason why I decided to be part of it.

Giuliana Giunta / M4DE CDT student

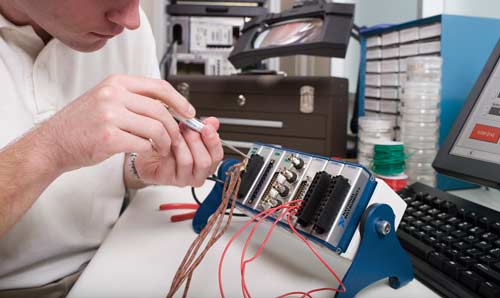

Skills training focused on advanced techniques, including electron microscopy, x-ray tomography, and photoelectron spectroscopy, with courses covering:

- research computing

- basic programming

- software engineering

- data interpretation and research data management.

Industrial secondments provided insights into real-world scientific issues, allowing our doctoral researchers to apply their expertise to find solutions; and skillsets further enhanced through outreach activities.

Research with industry

We were privileged to collaborate with a high level of expertise from our industry partners, whose input was crucial in ensuring the programme met the needs of the materials industry.

This collaboration enabled our students to apply their knowledge in sectors ranging from the pharmaceutical industry to energy providers and the automotive trade, gaining a well-rounded educational experience and addressing societal challenges in a variety of areas.

Explore our notable industrial partners

The following organisations sponsored one or more M4DE CDT projects:

- AkzoNobel

- Amec Foster Wheeler (now Wood)

- Atomic Weapons Establishment

- BAE Systems

- Bawtry Carbon International

- BCW Manufacturing Group

- BP

- Cellbond

- Continental Tyres

- Cullham Centre for Fusion Energy

- Defence Science and Technology Laboratory

- EDF Energy

- Exova

- Frazer-Nash

- GlaxoSmithKline

- Grundfos

- Hitachi

- M&I Materials

- National Physical Laboratory

- Rolls-Royce

- Sellafield

- SKF

- Tetra Pak

- TISICS

- Victrex

- Wallwork HT

- Waters

Research outputs

Working closely with industry partners, our Doctoral Researchers undertook a wide-range of research projects. Some research outputs can be found on Google Scholar.

Public engagement and outreach

A key component of the M4DE CDT programme was its public engagement and outreach. Collaborating with local schools and colleges in STEM-related activities and research placements enhanced skillsets and the program's societal impact.

"I'm very grateful for the help we've had this year from your PhD students. They all have a superb ability to communicate what they do enthusiastically. Our students in Years 8, 10 and 12 have all really enjoyed the sessions they planned and delivered, so thanks! One of my A Level Physics students is now considering Materials or Engineering at University so they definitely made a good and lasting impression"

Rob Martin - Physics Teacher at Darwen Aldridge Community Academy

Academic leadership

-

Director: Dr Rob Lindsay

Dr Rob Lindsay is a Reader in Corrosion Science and Engineering at the School of Materials, The University of Manchester. With over 25 years of research experience, he has held positions at other prestigious institutions such as the Fritz-Haber-Institut in Berlin and Cambridge University. He has authored over 80 published articles, focusing on surface/interface properties relevant to corrosion and oxide surface chemistry. His research involves understanding corrosion inhibition mechanisms, atmospheric corrosion, and the interfacial structure of materials, among other topics.

Read Dr Lindsay's research profile

-

Director: Prof Phil Withers

Professor Withers earned his PhD in Metallurgy from Cambridge University and took up a lectureship there, before taking up a Chair in Manchester in 1998. His interests lie in applying advanced techniques to follow the behaviour of engineering and natural materials in real time and in 3D, often as they operate under demanding conditions. In 2005 he was elected to the Royal Academy of Engineering and in 2008 set up the Henry Moseley X-ray Imaging Facility, which is now one of the most extensive suites of 3D X-ray Imaging facilities in the world.

Read Prof Withers research profile

-

Associate Director: Prof John Francis

John joined The University of Manchester as a Senior Lecturer in 2011 and was promoted to a Readership, and subsequently a Chair in Materials Welding and Joining. John is a Fellow of the Institute of Materials, Minerals and Mining, and is accredited as a European/International Welding Engineer (EWE/IWE). John has been working with welding and cladding technologies for more than 20 years, having started his career with CSIRO in Australia, where he spent 7 years developing welding procedures to solve issues in the aerospace, power generation and minerals processing sectors.

Read prof Francis's research profile

-

Associate Director: Dr Matthew Roy

Dr Roy earned a Masters in Mechanical and Materials Engineering, and a PhD in Materials Engineering. He has worked on industry-driven research projects that focus on design, advanced manufacturing and materials processing. He joined The University of Manchester in 2013 as a Research Associate in weld modelling where he coordinated research into predicting and characterising residual stress and weld metallurgy. His principal research interests are advanced manufacturing and materials processing, linking processing methodology to the in-service life of resulting components.

Read Dr Roy's research profile

We are proud to introduce our academic staff who led this programme with their broad scope of knowledge and industry contacts - including oil and gas production, paint manufacture, transport and nuclear power generation.

Recruitment

Looking for a programme accepting applications?

- Explore our types of research degrees

- Contact our Doctoral Academy for recruiting centres.

Our graduates don't just leave as experts in their research niche; they gain a broad skill set, a wider understanding of power sector challenges, and a network of lifelong colleagues.